Cycle counts¶

For most companies, warehouse stock only needs to be counted once a year. This is why, by default, after making an inventory adjustment in Odoo, the scheduled date for the next inventory count is set for the 31st of December of the current year.

However, for some businesses, it’s crucial to have an accurate inventory count at all times. These companies use cycle counts to keep critical stock levels accurate. Cycle counting is a method by which companies count their inventory more often in certain locations, to ensure that their physical inventory counts match their inventory records.

Configuration¶

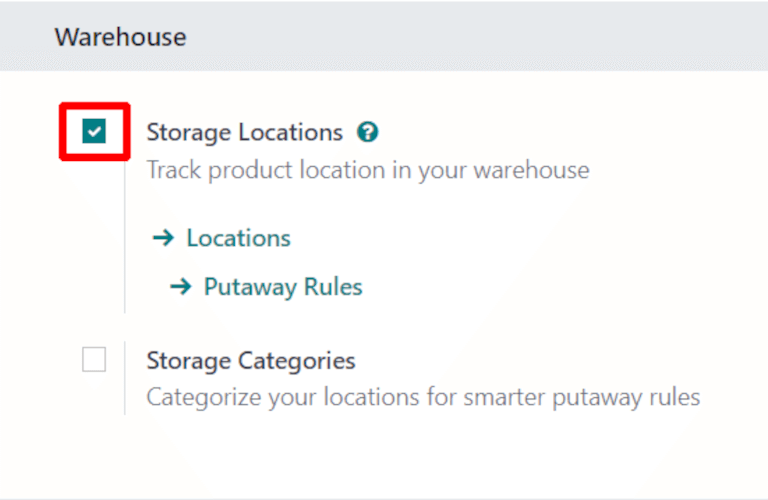

In Odoo, cycle counts are performed by location. Therefore, the Storage Locations feature needs to be enabled before performing a cycle count.

To enable this feature, navigate to , and scroll down to the Warehouse section. Then, tick the checkbox next to Storage Locations, and click Save.

Change inventory count frequency by location¶

Once the Storage Locations feature is enabled, and there are multiple locations created in the warehouse, the inventory count frequency can be changed for specific locations.

To view and edit locations, navigate to . This reveals a Locations page containing every location currently created and listed in the warehouse.

From this page, click into a location to reveal the settings and configuration page for that location.

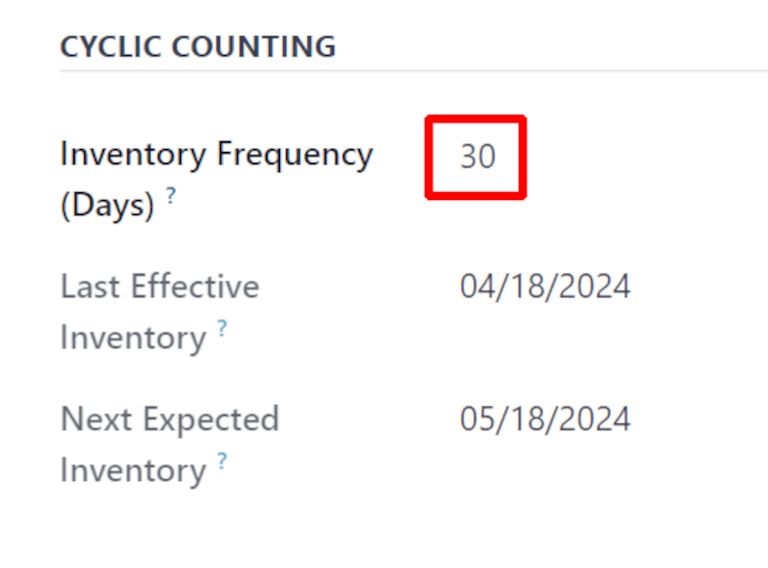

Under the Cyclic Counting section, locate the Inventory Frequency (Days)

field, which should be set to 0 by default (if this location has not been edited previously). In

this field, change the value to any number of days desired for the frequency of counts.

Example

A location that needs an inventory count every 30 days should have the Inventory

Frequency (Days) value set to 30.

Now, once an inventory adjustment is applied to this location, the next scheduled count date is automatically set, based on the value entered into the Inventory Frequency (Days) field.

Count inventory by location¶

To perform a cycle count for a specific location in the warehouse, navigate to . This reveals an Inventory Adjustments page containing all products currently in-stock, with each product listed on its own line.

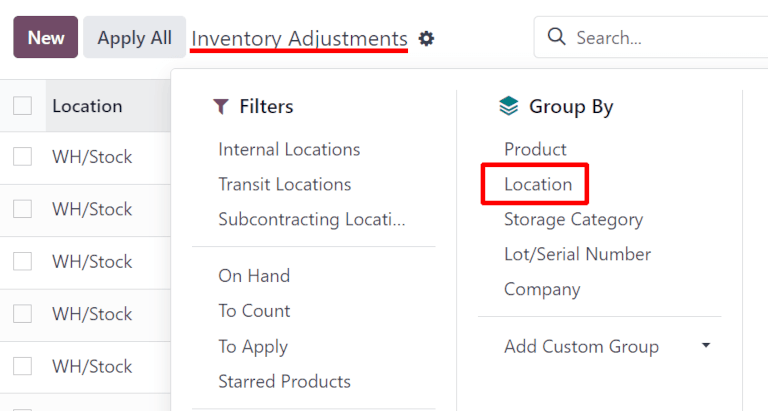

From this page, the Filters and Group By options (accessible by clicking the ⬇️ (down arrow) icon, to the right of the Search… bar), can be used to select specific locations and perform inventory counts.

To select a specific location, and view all products within that location, click the ⬇️ (down arrow) icon, to the right of the Search… bar. Then, in the Group By column, click Add Custom Group to reveal a new drop-down menu.

Click Location from the drop-down menu. Doing so sorts products into their storage locations on the Inventory Adjustments page, and a cycle count can be performed for all products in that location.

Tip

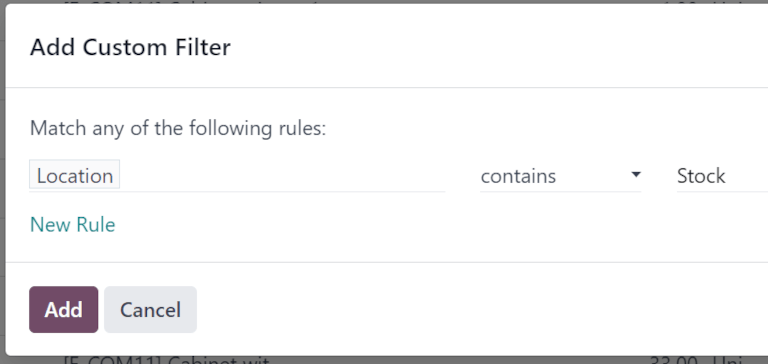

In large warehouses with multiple locations and a high volume of products, it might be easier to search for the specific location desired. To do this, from the Inventory Adjustments page, click the ⬇️ (down arrow) icon to the right of the Search… bar.

Then, in the Filters column, click Add Custom Filter to open an Add Custom Filter pop-up window.

In the first field, click the value and select Location from the list of options. Select contains in the second field. In the third field, type in the name of the location being searched for.

Click Add for that location to appear on the page.

Change full inventory count frequency¶

While cycle counts are typically performed per location, the scheduled date for full inventory counts of all in-stock products in the warehouse can also be manually changed, to push the date up sooner than the date listed.

To modify the default scheduled date, go to . Then, in the Operations section, locate the Annual Inventory Day

and Month setting field, which includes a drop-down field that is set to 31 December,

by default.

To change the day, click the 31, and change it to a day within the range 1-31, depending on the

desired month of the year.

Then, to change the month, click December to reveal the drop-down menu, and select the desired month.

Once all necessary changes have been made, click Save.

See also